Press machines are critical equipment in modern manufacturing, used for metal forming, stamping, punching, and bending operations. As industries demand higher productivity, precision, and safety, press machine manufacturers continuously adopt technological advancements to improve machine performance and efficiency. Innovations in automation, control systems, materials, and safety have transformed the way these machines are designed, built, and operated. These advancements not only increase output but also enhance reliability and reduce operational risks.

A reputable Press Machine Manufacturer incorporates cutting-edge technologies into their production process to ensure precision, efficiency, and safety. Modern press machines are no longer simple mechanical devices; they are integrated systems that combine mechanical, hydraulic, and electronic components. Technological improvements in design, materials, and control systems enable manufacturers to produce machines capable of handling complex operations while maintaining consistent quality. By leveraging these innovations, manufacturers can meet the growing demands of industrial clients worldwide.

Automation and Robotics Integration

One of the most significant technological advancements in press machine manufacturing is the integration of automation and robotics. Automated material handling systems, robotic feeders, and pick-and-place mechanisms reduce human interaction with the machine, minimizing safety risks and increasing production speed. Automation allows for continuous operation without fatigue-related errors, which is essential for high-volume production in automotive, electronics, and appliance manufacturing.

Robotic integration also enables precise alignment of workpieces, reducing material wastage and ensuring consistent output. In combination with advanced sensors and programmable logic controllers (PLCs), robotic systems provide accurate and repeatable operations, making modern press machines highly efficient and reliable.

CNC and Servo Control Systems

Computer Numerical Control (CNC) and servo motor technologies have revolutionized press machine operation. CNC systems allow precise control of ram movement, stroke length, and force, ensuring accurate results in stamping, forming, and punching processes. Servo presses offer variable speed, position, and force control, allowing manufacturers to handle delicate components or complex geometries with minimal material deformation.

The use of CNC and servo systems also improves flexibility, enabling quick changes in production settings for different part designs. This adaptability reduces downtime, enhances efficiency, and supports just-in-time manufacturing practices. Combined with automated data collection, these systems allow operators to monitor performance and make real-time adjustments for optimal results.

Advanced Materials and Manufacturing Techniques

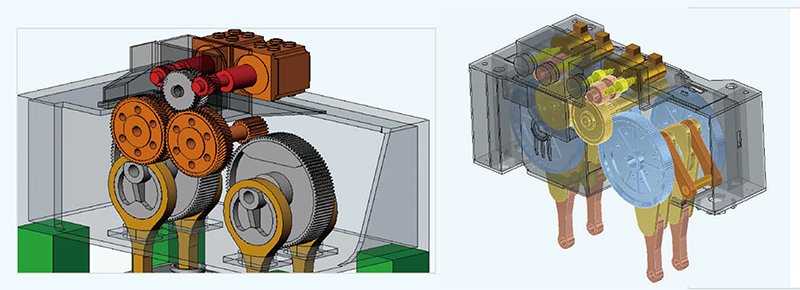

Technological advancements are not limited to electronic systems. Modern press machine manufacturers also utilize advanced materials and manufacturing techniques to enhance machine durability and performance. High-strength alloys, hardened steels, and lightweight composites are used in critical components such as frames, rams, and gears. These materials increase structural integrity, reduce wear, and extend the service life of machines.

Precision fabrication techniques, including CNC machining, laser cutting, and additive manufacturing, allow for tighter tolerances and complex geometries. By adopting these methods, manufacturers can produce machines that are more robust, precise, and capable of handling higher operational loads without compromising safety or efficiency.

Safety Enhancements Through Technology

Safety has always been a critical concern in press machine operations, and technological advancements have significantly improved operator protection. Modern machines feature integrated safety systems such as light curtains, interlocks, pressure-sensitive mats, and two-hand operation controls. Advanced sensors detect unsafe conditions and automatically stop the machine, preventing accidents before they occur.

Additionally, digital monitoring and IoT-enabled systems provide real-time feedback on machine health, performance, and maintenance needs. Predictive maintenance reduces unexpected downtime and enhances safety by identifying potential failures before they lead to hazardous situations.

Energy Efficiency and Environmental Considerations

Energy efficiency is another area of innovation in press machine manufacturing. Variable frequency drives, regenerative systems, and optimized hydraulic circuits reduce energy consumption while maintaining performance. Lightweight and durable materials also reduce operational energy requirements. Manufacturers increasingly focus on environmentally friendly production by using sustainable materials, reducing waste, and implementing energy-efficient designs.

Data-Driven Manufacturing and Industry 4.0

The adoption of Industry 4.0 principles has transformed press machine manufacturing. IoT devices, sensors, and cloud-based monitoring systems allow manufacturers to collect and analyze performance data in real time. This data-driven approach enables predictive maintenance, process optimization, and continuous improvement. By leveraging analytics and machine learning, manufacturers can enhance efficiency, reduce costs, and improve product quality consistently.

Conclusion

Technological advancements in press machine manufacturing have transformed traditional equipment into sophisticated, precise, and efficient industrial tools. Automation, robotics, CNC and servo control, advanced materials, safety innovations, energy efficiency, and data-driven monitoring have collectively improved performance, reliability, and operator safety. A reliable Press Machine Manufacturer leverages these advancements to produce machines that meet the demands of modern industrial production. By integrating technology into design, fabrication, and operation, manufacturers can ensure that press machines are not only productive and precise but also safe, durable, and energy-efficient, meeting the evolving needs of the manufacturing sector worldwide.