The production of laundry pods involves handling chemicals, precise machinery, and high-speed processes, making safety a top priority for manufacturers. Modern laundry pod machines are designed not only to produce high-quality pods efficiently but also to protect operators and maintain a safe working environment. With advanced engineering and integrated safety systems, these machines reduce risks while ensuring consistent performance and product quality.

Importance of Safety in Laundry Pod Production

Safety is a critical concern in laundry pod production due to the chemical composition of detergents and the complexity of the machines used. Operators can be exposed to concentrated detergents, high temperatures, and moving parts, which may result in chemical burns, cuts, or other injuries if proper safety measures are not in place.

Modern machines address these risks through automated systems and protective features that minimize human contact with hazardous components. Machines like the Laundry Pod Machine are designed to combine operational efficiency with safety, providing secure enclosures, automated controls, and emergency response systems that protect both operators and the product.

Emergency Stop Mechanisms

One of the most basic yet essential safety features in modern laundry pod machines is the emergency stop mechanism. These systems allow operators to immediately halt machine operations in the event of an accident, equipment malfunction, or abnormal process.

Emergency stop buttons are strategically placed around the machine to ensure quick access from any point. Some advanced machines integrate electronic interlocks that stop the machine automatically if protective panels are opened or if sensors detect abnormal movement, temperature, or pressure. This feature reduces the risk of injury and prevents damage to the machine or the pods being produced.

Protective Enclosures and Guarding

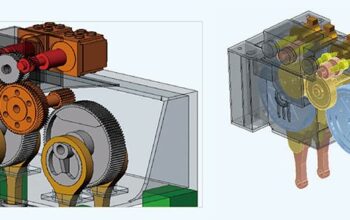

Modern laundry pod machines use protective enclosures and guarding to prevent operator exposure to moving parts and hazardous areas. Transparent covers or panels allow operators to monitor the production process safely while preventing accidental contact with rollers, cutters, or sealing units.

These enclosures are often designed to be interlocked with the machine’s control system. When a panel is opened for maintenance or inspection, the machine automatically stops operating, ensuring that operators can work safely. Protective guarding also helps maintain a clean production environment by preventing dust, detergent particles, or debris from spreading outside the machine.

Automated Chemical Handling

Detergent formulations used in laundry pods can be corrosive, toxic, or irritating if handled improperly. Modern machines incorporate automated dosing and dispensing systems to minimize human contact with these chemicals.

Automated pumps, piston fillers, and volumetric dosing systems allow precise measurement and delivery of liquid, gel, or powder detergents directly into the pods without manual handling. This not only improves accuracy and consistency but also protects operators from chemical exposure. Some machines are equipped with sealed chemical tanks and tubing systems to further enhance safety during production.

Sensor-Based Safety Systems

Advanced sensor technology is a hallmark of modern laundry pod machines. Sensors monitor critical aspects of production, such as temperature, pressure, alignment, and pod integrity, ensuring the machine operates within safe parameters.

If a sensor detects an issue, such as a jammed film, a misaligned mold, or a leaking pod, the machine automatically stops, and an alert is issued to the operator. These proactive systems prevent accidents, reduce material waste, and allow operators to address problems before they escalate.

Ergonomic and Operational Safety

Operator safety also extends to ergonomics and workflow design. Modern machines are designed to minimize the need for repetitive motions, excessive bending, or manual lifting. Control panels and interfaces are positioned for easy access, reducing strain on operators.

Human-machine interfaces (HMI) allow operators to monitor and adjust production parameters without direct contact with hazardous components. Automated cleaning and maintenance procedures further reduce operator exposure to detergents and high-speed machinery, creating a safer and more efficient work environment.

Fire and Electrical Safety

High-speed laundry pod machines often operate with heating elements for sealing pods and motors for material handling. Modern machines include fire-resistant materials, temperature controls, and circuit protection to prevent overheating or electrical hazards. Thermal sensors and fuses ensure that any irregularity triggers an automatic shutdown, protecting both the machine and the operators.

Conclusion

Safety is a critical aspect of modern laundry pod production, and manufacturers must prioritize it alongside efficiency and quality. Features such as emergency stop mechanisms, protective enclosures, automated chemical handling, sensor-based monitoring, ergonomic design, and fire and electrical safeguards work together to create a secure production environment.

Investing in a high-quality Laundry Pod Machine ensures that manufacturers can produce high volumes of pods efficiently while protecting operators from potential hazards. By integrating safety into machine design and operations, businesses can reduce risks, maintain consistent product quality, and comply with industry regulations, ultimately creating a safer and more productive manufacturing environment.