The extraction of treasured substances from the soil calls for mining and blasting activities. An essential piece of equipment that impacts the effectiveness and outcome of the drilling procedure, the drill rig is in the middle of these operations. Understanding the important additives to affect performance, safety, and price-effectiveness is important when considering shopping for a rig for mining or blast drilling. The vital factors to take into account while purchasing a mining or blast drill rig are examined in this blog.

Drilling Diameter and Depth

The depth and diameter that the rig can drill is one of the most important things to take into account. The depth capacity should match the specifications of the mining or blasting needs you have in mind. It’s important to choose a drill rig size that corresponds with the ore body’s depth and the prevailing geological conditions. Likewise, how well the blasting procedure and the ensuing mineral extraction go will depend on the diameter of the drill hole.

Performance and Power

One of the most important factors is a drill rig’s power. The horsepower of the engine and the kind of drill it utilizes are major factors in rig performance. Stronger rigs can work faster and with greater strength, which can greatly increase productivity in difficult rock formations. Check the rig’s power-to-weight ratio to make sure it can manage the unique requirements of your business while being effective.

Adaptability and Swiftness

Tough terrain is a common place for blast drilling and mining. For this reason, the drill rig’s mobility is crucial. Examine the rig’s capacity to maneuver through confined places and uneven terrain, and decide if it is tracked or wheeled. Because they save downtime and provide simple positioning and repositioning inside the mining site, rigs featuring sophisticated mobility capabilities can improve operational efficiency.

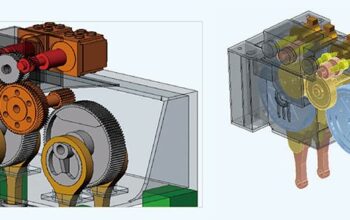

Drilling Mechanism and Technology

A multitude of mechanisms and technology are installed in modern drill rigs, which might affect how well they work. When it comes to drilling speed and control, hydraulic systems are superior to pneumatic systems, which are more antiquated. Further improving accuracy and lowering the need for human intervention are two other benefits of automated and semi-automatic drilling systems, which raise safety and efficiency.

Features for Safety

Mine and blasting activities must prioritize safety. For the safety of both the operator and the surrounding area, a drill rig needs to have a full range of safety features. Search for vehicles equipped with cutting-edge safety features including strong safety guards, emergency stop controls, and automated shut-off mechanisms. For a safe working environment, take into account rigs that adhere to industry safety norms and laws.

Ease of maintenance and serviceability.

Yet another important thing to think about is maintenance ease. Maintaining drill rigs is crucial to their operation because they are exposed to severe environments and constant wear and tear. Select a rig that has easy-to-reach parts for regular maintenance and inspection. To save downtime and maintain the rig in top operating condition, take into account the availability of spare parts as well as the support provided by the dealer or manufacturer.

Economy of Fuel and Running Expenses

A major factor to take into account when buy rig for mining is operating costs. An operation’s total cost is directly impacted by fuel efficiency. Seek out rigs with higher fuel consumption rates that don’t sacrifice functionality. Furthermore, assess other operating expenses including upkeep, repairs, and training needs. You may increase the total profitability of your mining or blasting business by making long-term savings with more economical and fuel-efficient equipment.

Effect on Environment

Mining activities are becoming more and more dependent on environmental factors. Drill rig emissions, noise levels, and the possibility of environmental contamination are some of the aspects that affect the environment. Select rigs with eco-friendly features and those that follow environmental rules. A more ecologically friendly and sustainable operation can be achieved by selecting rigs with reduced emissions and noise levels.

Comfort and Ergonomics of the Operator

The operator cabin’s ergonomics and comfort are important but sometimes disregarded, especially for guaranteeing operator productivity and minimizing tiredness. Operator working conditions may be improved with features like movable seats, climate control, and intuitive controls. Long-shift productivity can be increased and operator strain can be decreased with a well-designed and comfortable cabin.

Personalized and Flexible Approach

And last, think about how easily the rig can be modified to fit particular operational requirements. To handle diverse drilling activities or geological conditions, certain drilling rigs can be equipped with different accessories or modifications. Look into whether the rig may be customized to meet the special needs of your blasting or mining activities, giving you more freedom and adaptability.

Conclusion:

An important decision that impacts the efficacy, safety, and economy of your mining and blast drilling operations is selecting the appropriate drill rig. Make an informed decision that fits your operational needs and goals by carefully weighing the important features covered in this blog, including drilling depth, power, mobility, technology, safety, maintenance, fuel efficiency, environmental impact, operator comfort, and customization. The success and sustainability of your mining initiatives will be improved and enhanced when you invest in the proper drill rig.