Inflatable tents have become a preferred solution for outdoor events, promotional activities, and recreational use due to their portability, ease of setup, and durable design. However, ensuring that these tents perform reliably under various environmental conditions requires rigorous testing during manufacturing. Inflatable tent factories implement a series of testing procedures to verify material integrity, structural stability, air retention, and overall safety. These measures are critical to delivering high-quality tents that meet both industry standards and customer expectations.

Material Inspection and Verification

The first stage of testing in an inflatable tent factory involves thorough material inspection. Fabrics used for the outer shell, such as PVC-coated polyester, nylon, or oxford cloth, are examined for strength, waterproofing, and UV resistance. Similarly, the inflatable chambers, often made from thermoplastic polyurethane (TPU) or reinforced PVC, are tested for flexibility, durability, and airtightness. Pre-production testing ensures that defective materials are identified early, preventing potential failures during assembly or in the field. An Inflatable Tent Factory relies on these inspections to maintain consistent product quality and reduce the likelihood of warranty claims or customer complaints.

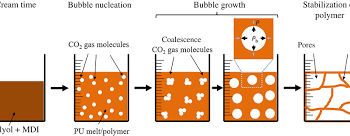

Seam and Weld Testing

Seams and welds are critical to the performance of inflatable tents, as they ensure the chambers remain airtight under pressure. High-frequency or heat-welded seams are tested for tensile strength and airtightness. Factories often use air pressure tests or vacuum chambers to detect leaks or weak points in the welded sections. Any seam that fails these tests is repaired or replaced to prevent structural issues. This testing is essential because even minor defects in seams can lead to significant air loss, compromising the stability and safety of the tent.

Inflation and Pressure Testing

Inflation testing is a core procedure conducted in inflatable tent factories. Each tent is fully inflated using the intended pumping system, and internal air pressure is monitored to ensure uniform distribution across all chambers. Sensors and gauges measure the pressure levels to verify that the tent maintains its shape under operational conditions. Multi-chamber tents are tested for synchronized inflation to ensure no chamber is over-pressurized or under-pressurized. This testing guarantees that the tent can be set up quickly and remains stable during use, which is especially important for commercial and promotional applications.

Environmental and Weather Simulations

Inflatable tents are often exposed to varying weather conditions, so environmental testing is critical. Water resistance tests simulate heavy rain to ensure the fabric and seams prevent leakage. Wind tunnel or fan simulations test the structural stability of the tent under strong gusts. Additionally, UV exposure tests are conducted to determine the material’s resistance to sunlight degradation over time. These tests confirm that the tents can endure outdoor conditions without compromising performance or safety.

Load and Stress Testing

Structural testing involves applying external loads to assess the tent’s durability. This can include weight tests on the fabric, pulling forces on anchor points, and stress simulations on critical junctions. Load testing ensures that the tent’s design can handle real-world forces without tearing, collapsing, or losing shape. Stress testing is particularly important for larger tents, where multiple chambers and heavier structures must work together to maintain stability.

Valve and Inflation System Checks

The valves and inflation systems are another focus of testing in inflatable tent factories. Valves are tested for airtight sealing and durability under repeated use. Pumps and automated inflation systems are checked for performance, speed, and reliability. Properly functioning valves and inflation systems are essential for rapid setup and long-term usability. These tests prevent common operational issues such as slow inflation, uneven pressure, or accidental deflation during use.

Final Inspection and Quality Assurance

After completing all technical tests, the tent undergoes a final inspection for overall quality and functionality. This includes checking doors, windows, ventilation panels, and any customized branding elements. The final inspection ensures that the tent meets both internal standards and external regulatory requirements. Documentation of test results and quality checks is maintained to provide traceability and accountability.

Conclusion

Testing procedures in inflatable tent factories are comprehensive and multifaceted, covering material inspection, seam integrity, inflation performance, environmental resistance, load handling, and valve functionality. Each stage of testing ensures that the final product is safe, durable, and reliable for end users. By rigorously assessing every aspect of design and assembly, modern Inflatable Tent Factory operations deliver tents capable of performing under diverse conditions while maintaining high standards of quality and safety. These testing practices not only enhance customer confidence but also reinforce the reputation of manufacturers in a competitive market.