Metal fabrication is a critical process in industries ranging from automotive to construction and electronics. Achieving precision, efficiency, and consistency in metalwork requires advanced machinery that can handle high-volume operations while maintaining accuracy. Among the most essential tools in modern fabrication workshops is the power punch machine. Designed to cut, shape, and form metal sheets with precision, these machines provide numerous advantages that significantly enhance production capabilities.

Enhanced Efficiency and Speed

One of the primary advantages of a power punch machine is its ability to perform operations quickly and efficiently. Unlike manual punching methods, which are labor-intensive and time-consuming, a power punch machine uses mechanical or hydraulic force to punch metal sheets rapidly. The automation of repetitive tasks allows manufacturers to produce large quantities of parts in a fraction of the time required for manual operations. Leading Power Punch Machine models are capable of executing complex punching sequences with minimal human intervention, significantly increasing overall productivity and enabling businesses to meet tight production deadlines.

High Precision and Consistency

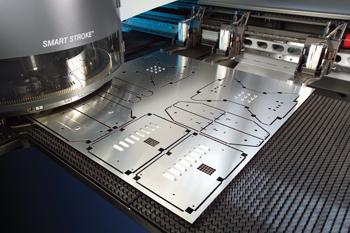

Precision is essential in metal fabrication, especially for applications that demand tight tolerances and uniformity. Power punch machines offer unparalleled accuracy, ensuring that every hole, slot, or shape is cut consistently. The integration of computer numerical control (CNC) systems in modern machines allows operators to program exact specifications, which the machine follows with high repeatability. This level of precision not only reduces material waste but also ensures that fabricated components fit together perfectly, enhancing the quality of the final product. Consistency in production is particularly beneficial for industries like aerospace and electronics, where small deviations can lead to significant functional issues.

Versatility in Applications

Power punch machines are versatile tools capable of handling a wide variety of metal fabrication tasks. With interchangeable punches and dies, these machines can create different shapes, sizes, and patterns on metal sheets. This versatility makes them suitable for multiple applications, from creating small components like brackets and enclosures to larger structural elements. Fabricators can switch dies and adjust settings to accommodate various materials, including steel, aluminum, and copper, without the need for multiple specialized machines. This adaptability reduces the need for additional equipment and lowers overall operational costs.

Reduction in Labor Costs

Automation is one of the key benefits of power punch machines, and it directly impacts labor requirements. Since these machines can perform repetitive tasks without constant manual input, fewer operators are needed to maintain production levels. This reduction in labor not only lowers operational costs but also minimizes the risk of human error, improving overall safety and efficiency. Additionally, operators can focus on higher-value tasks such as machine setup, quality control, and workflow optimization, further enhancing the productivity of the fabrication shop.

Improved Safety in Fabrication Processes

Safety is a critical concern in metal fabrication, and power punch machines are designed with operator protection in mind. Modern machines include safety features such as emergency stop buttons, protective guards, and light curtains, which prevent accidents during operation. Automated material handling systems also reduce manual interaction with heavy or sharp metal sheets, decreasing the likelihood of injuries. By minimizing risks, these machines create a safer work environment while maintaining high production efficiency.

Cost-Effectiveness Over Time

While the initial investment in a power punch machine may be higher than manual or simpler alternatives, the long-term benefits make it a cost-effective choice. The combination of high-speed operation, reduced labor, minimal material waste, and consistent quality leads to significant savings over time. Additionally, the durability of these machines ensures long-term reliability with proper maintenance, reducing the need for frequent replacements or repairs. Businesses that invest in high-quality power punch machines often experience improved ROI and sustainable operational efficiency.

Integration with Modern Manufacturing Technologies

Many power punch machines are now equipped with smart technology, IoT integration, and CNC systems, allowing for enhanced monitoring and control. Operators can track performance metrics, schedule preventive maintenance, and optimize production workflows. The ability to integrate with automated material handling systems and other fabrication equipment further improves operational efficiency. These technological advancements make power punch machines not only a tool for punching metal but also an essential component of modern, connected manufacturing systems.

Conclusion

The advantages of using a power punch machine for metal fabrication are extensive. From enhanced efficiency and high precision to versatility, safety, and long-term cost-effectiveness, these machines provide significant value for industrial operations. By incorporating automation and advanced control systems, a power punch machine ensures consistent, high-quality results while reducing labor costs and material waste. Investing in reliable equipment, such as a Power Punch Machine, allows fabricators to improve productivity, maintain competitive advantage, and achieve operational excellence in today’s demanding manufacturing environment.