You know when you speak of a spline impact socket, it is a special type of tool that professionals use to tighten or loosen bolts and nuts. It is primarily used in heavy-duty work in which regular sockets may break or get damaged. These sockets are specifically designed to handle robust forces from impact wrenches. To pick the right spline impact socket is critical because it helps you work safely, efficiently , and even without damaging your tools or parts. You can speak with expert spline impact socket supplier to get the best tools. For now, read on to know what to consider:

Overall Material Quality

The material that gets used to make the socket is very important. Spline impact sockets should be strong and long-lasting. Look for sockets formed up of high-quality steel. The material must be heat -treated so that it can resist pressure, even wear, and tear. Poor-quality sockets may crack or even break easily and that can be dangerous. A robust material will also last longer and even save you pennies in the long run. Always make sure that you do check if the socket is labeled as impact-rated or even heavy-duty. Such a thing means it is constructed for tough jobs.

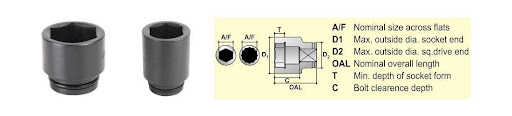

Proper Size and Fit

Spline sockets are available in different sizes to fit different bolt heads. You should choose the correct size for the job. A socket that is too loose can slip and even harm the bolt or hurt your hand. A socket that is too tight won’t simply fit at all. Spline sockets are effective and useful because they can often fit multiple bolt types like:

- 6-point

- 12-point

- even square or rounded types of fasteners.

Now, in case you are someone who works with many types of bolts, a spline socket set having various sizes is a great idea.

Compatibility of Drive Size

The drive size is the proper part of the socket that connects to the tool, like a wrench or even a ratchet. Common drive sizes include:

- 1/4-inch

- 3/8-inch

- 1/2-inch

- 3/4-inch.

You should go for a spline socket that matches your tool’s drive size. If the drive size does not really go well with or match, you won’t be able to use it, or you might need an adapter that may not be as strong. Always make sure that you do check your tool’s drive size before buying a new socket.

Effective Coating and Finish

The external coating of the socket helps protect it from rust and even makes it convenient for you to clean. Some sockets accompany a black oxide or phosphate finish, which helps in averting corrosion. This is immensely important if you work in wet, dirty, or even outdoor environments. A good coating even makes it easier to grip the socket once your hands are oily or wet. It would be nice for you if you choose a non-slip finish or texture that enhances your grip.

Conclusion

To sum up, going for the right spline impact socket is important for immense safety, proper efficiency, and even tool care. Once you take your time to choose wisely, it simply means you can work better and even safer every day. You can speak with a spline impact socket distributer and figure out more.