Water soluble packaging has become a critical solution for industries that prioritize convenience, safety, and environmental sustainability. From detergents and cleaning products to pharmaceuticals and healthcare applications, single-dose packaging in water soluble films is increasingly popular. As demand for these products grows, manufacturers face the challenge of scaling production without compromising quality. High-speed water soluble packaging machines provide an effective solution, enabling efficient, consistent, and sustainable packaging at large volumes.

The Need for High-Speed Packaging

Traditional water soluble packaging methods, including manual or low-speed machines, are often insufficient for meeting the requirements of modern manufacturing. High consumer demand, strict delivery timelines, and competitive markets require faster production rates without sacrificing precision. Low-speed systems may lead to bottlenecks, increased labor costs, and inconsistent package quality, particularly when handling delicate films that are sensitive to moisture and pressure.

High-speed water soluble packaging machines address these limitations by integrating automation, precision dosing, and synchronized operations. These systems are capable of handling liquids, powders, gels, and other formulations efficiently, maintaining consistent package size, weight, and seal integrity even at high output rates.

Features of High-Speed Water Soluble Packaging Machines

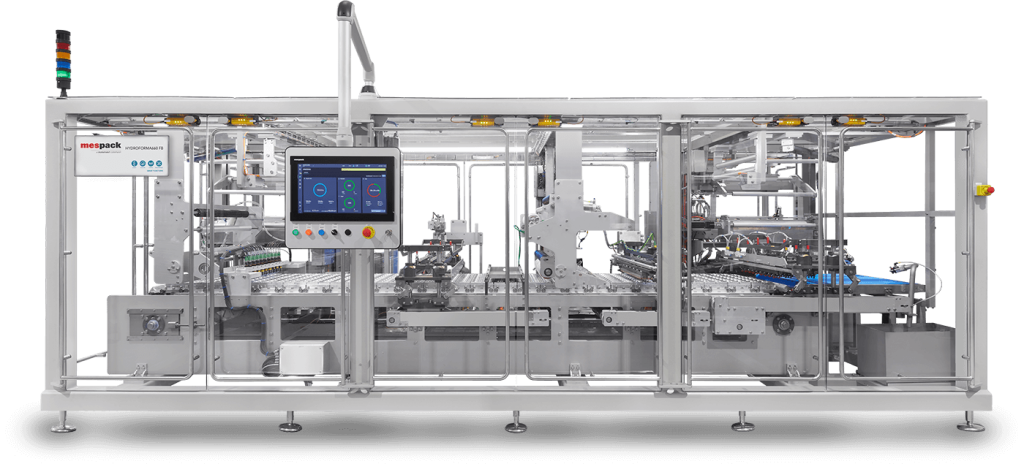

A modern Water Soluble Packaging Machine incorporates multiple features to support high-speed production while maintaining quality. Multi-lane configurations allow simultaneous packaging of several units, effectively multiplying output without requiring additional floor space. Automated filling systems, such as volumetric pumps or servo-controlled augers, ensure precise dosing for each package. Advanced sealing technologies, including heat sealing or ultrasonic sealing, provide strong and consistent seals even at high operational speeds.

Environmental controls, such as humidity and temperature regulation, protect the delicate water soluble films from premature dissolution or deformation. Real-time monitoring systems and sensors detect misfeeds, misalignments, or seal defects, allowing the machine to correct issues automatically and reduce material waste. Together, these features allow manufacturers to maintain high production efficiency while meeting the stringent quality standards required in pharmaceutical, healthcare, and chemical industries.

Advantages of Scaling Production

Scaling production with high-speed water soluble packaging machines offers multiple benefits. The most immediate advantage is increased throughput. Multi-lane, high-speed machines can produce tens of thousands of single-dose units per hour, far exceeding the capabilities of manual or slower machines. This enables manufacturers to meet growing market demand efficiently and reduces lead times for product delivery.

In addition to speed, these machines improve accuracy and consistency. Automated dosing, filling, and sealing processes reduce human error, ensuring that each package meets precise specifications. This is particularly important for pharmaceutical products or concentrated detergents, where correct dosage is critical for efficacy and safety. Consistent quality also enhances brand reputation and customer satisfaction.

High-speed machines also optimize resource utilization. By reducing downtime, minimizing waste, and handling multiple packaging lanes simultaneously, manufacturers can improve operational efficiency. Energy-efficient motors, precise sealing technologies, and optimized material handling contribute to lower electricity consumption per unit, supporting both cost savings and environmental sustainability initiatives.

Applications Across Industries

High-speed water soluble packaging machines are widely adopted across various sectors. In the detergent and cleaning industry, these machines produce laundry pods, dishwasher capsules, and concentrated cleaning agents in single-dose packs, offering convenience and safety for consumers. Industrial cleaning and hospitality sectors benefit from pre-measured chemical doses, reducing handling risks and ensuring proper application.

In pharmaceuticals, high-speed machines enable precise packaging of powdered medications, gels, or liquid formulations. Single-dose units reduce the risk of contamination, support accurate dosage, and improve patient safety. Hospitals, clinics, and healthcare providers rely on these machines to supply high-volume products efficiently without compromising hygiene or product integrity.

Maintenance and Operational Considerations

Even with advanced high-speed capabilities, proper maintenance is critical to ensure reliable performance. Regular cleaning, lubrication, and inspection prevent downtime and protect sensitive components. Maintaining environmental controls, such as humidity and temperature, ensures consistent operation and prevents damage to water soluble films. Skilled operators trained to monitor machine performance, handle issues, and perform preventive maintenance contribute to sustained high-speed efficiency and production quality.

Future Trends in High-Speed Packaging

As demand for water soluble single-dose products grows, manufacturers will continue to invest in high-speed packaging solutions. Future trends include increased automation, AI-based monitoring for predictive maintenance, and energy-efficient designs that reduce operational costs and environmental impact. Multi-functional machines capable of handling various product types, from powders to liquids, will provide greater flexibility and scalability in production lines.

Conclusion

High-speed water soluble packaging machines are essential for manufacturers seeking to scale production while maintaining quality, safety, and efficiency. By integrating automation, precision dosing, multi-lane configurations, and real-time monitoring, these machines enable high-volume production without compromising the integrity of delicate water soluble films. Industries such as detergents, pharmaceuticals, healthcare, and industrial cleaning benefit from faster output, reduced waste, and improved operational efficiency. Proper maintenance and operator training ensure that high-speed machines continue to deliver reliable and sustainable packaging solutions, meeting the growing demands of modern markets.