Efficient production workflow is essential for maintaining quality, reducing downtime, and maximizing output in precision manufacturing. Swiss lathe machines are particularly well-suited for small, complex components that require high accuracy and repeatability. Optimizing workflow around these machines can significantly enhance productivity and reduce operational costs.

Assess Production Needs

The first step in optimizing workflow is a thorough assessment of production requirements. Consider the type of components, batch sizes, material properties, and tolerance levels. Understanding these factors helps determine which machine features and configurations will support efficient production. For example, multi-axis capabilities or live tooling may be necessary for parts with complex geometries, while automation features may be more important for high-volume production.

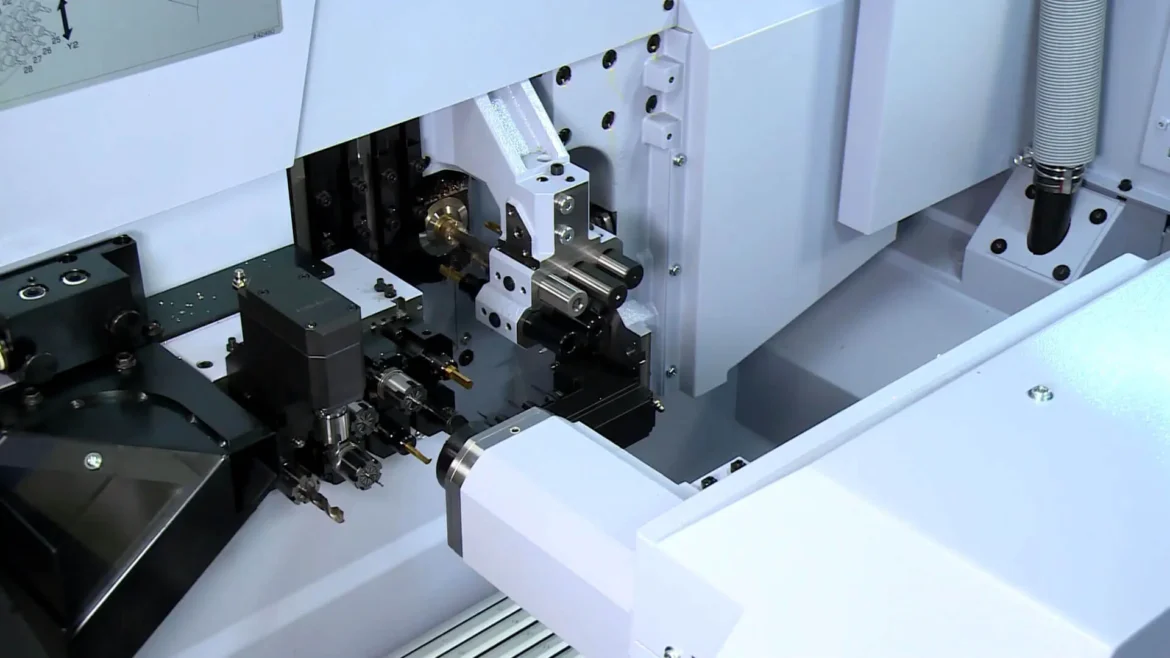

Configure the Machine for Efficiency

Proper configuration of the Swiss lathe machine is crucial for smooth operations. Tooling setups, spindle speeds, feed rates, and guide bushing alignment should be optimized according to the specific materials and part dimensions. Implementing standard operating procedures for setups and adjustments reduces setup times and minimizes errors. Integrating swiss lathe machine features such as bar feeders, automatic tool changers, and multi-axis machining ensures that production processes are streamlined, reducing manual interventions and improving overall efficiency.

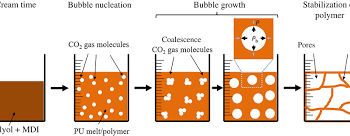

Streamline Material Handling

Efficient material handling plays a significant role in workflow optimization. Automated bar feeders and proper workpiece support reduce handling errors and prevent deflection or damage during machining. Positioning materials and finished parts strategically within the workspace also improves operator efficiency and reduces cycle times. Maintaining an organized system for raw materials, tools, and finished components helps prevent production bottlenecks.

Implement Automation and Monitoring

Automation enhances workflow by minimizing operator intervention and ensuring consistent production. Features such as automatic tool changes, in-process monitoring, and error detection systems allow the machine to operate continuously with minimal supervision. Real-time monitoring helps detect potential issues early, preventing defects and downtime. For small-batch or high-mix production, automation ensures that workflow remains efficient even when part designs or materials change frequently.

Optimize Tooling and Maintenance

Tooling selection and maintenance directly impact productivity and component quality. Regular inspection and timely replacement of cutting tools maintain optimal performance. Ensuring that all tooling is correctly installed, aligned, and calibrated minimizes machining errors and scrap. Additionally, proactive maintenance of the Swiss lathe, including lubrication, spindle checks, and guide bushing alignment, supports consistent performance and prevents unplanned downtime.

Standardize Procedures and Training

Standardizing operational procedures is essential for efficient workflow. Operators should follow consistent methods for setup, programming, and machine operation. Comprehensive training ensures that all personnel are proficient with machine functions, CNC programming, and troubleshooting. A skilled workforce reduces mistakes, speeds up production, and maintains quality standards across multiple shifts or operators.

Monitor Performance and Optimize Processes

Collecting and analyzing production data can reveal opportunities to improve workflow. Track cycle times, tool wear, downtime, and defect rates to identify inefficiencies or bottlenecks. Adjust machine parameters, scheduling, and production sequencing based on these insights. Continuous improvement initiatives supported by data analysis ensure that workflow optimization is ongoing and responsive to changing production demands.

Integrate Workflow with Other Operations

Optimizing workflow extends beyond the machine itself. Coordinating Swiss lathe operations with upstream and downstream processes, such as material preparation and inspection, ensures a smooth flow of components. Minimizing delays between operations, synchronizing production schedules, and reducing idle time improve overall efficiency and throughput. This holistic approach enhances productivity across the entire manufacturing system.

Conclusion

Optimizing production workflow with a Swiss lathe machine involves careful assessment of production needs, proper machine configuration, efficient material handling, and effective automation. Tooling management, routine maintenance, standardized procedures, and performance monitoring further enhance efficiency. By integrating these practices, manufacturers can achieve consistent quality, reduce downtime, and maximize output, ensuring that the Swiss lathe delivers its full potential in precision component production.