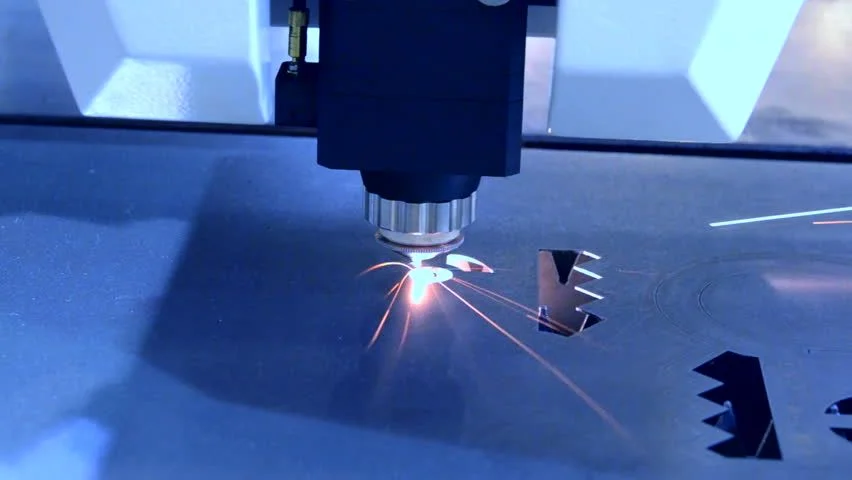

The manufacturing industry in Dubai has seen impressive technological developments. The pressure to implement the tools to improve the accuracy, efficiency, and design flexibility has flourished due to the attention of the region to innovation and industrialization. Among the technologies that have been revolutionizing the industry, beam laser cutting in Dubai has become one of the most important innovations. This technology, which is also propelled by speed and error-free precision, has transformed how firms produce parts and components by ensuring that quality is always maintained and that the production process is accelerated.

Outstanding Quality and Exceptional Edge Finishing

The finishing step is one of the difficulties with conventional cutting methods. Warping, distortions, burrs, and rough edges are frequently the results of mechanical cutting. By creating flawless edges in a single step, professional beam laser cutting in Dubai has all but eradicated these issues. Cuts produced by the concentrated laser beam’s accuracy are deformity-free and require little to no further finishing procedures.

Materials maintain their structural integrity during the process thanks to this polished edge quality. It is possible to cut non-metallic materials, thin sheets, and sensitive alloys without causing obvious distortion or heat damage. Such a superb finish guarantees both practicality and visual appeal, especially in fields where visual presentation is crucial, like architecture or product design.

Increasing Production Efficiency and Speed

In Dubai’s fiercely competitive manufacturing climate, production speed is essential. Expert beam laser cutting distinguishes itself by fusing exceptional accuracy with quick operation. Traditional techniques could call for extra processing, or they might need several passes to produce intricate cuts. Beam laser cutting, on the other hand, completes several tasks in one run

Fast task switching is another benefit of the technology’s digital integration. Project transitions happen quickly after designs are digitally entered into the system. As a result, high throughput is attained, allowing companies in Dubai to provide quicker turnaround times. Efficiency is increased and production timeframes are shortened by increasing cycle speed while maintaining accuracy.

Design Liberty in Contemporary Production

Mass manufacture of homogeneous designs is no longer the only focus of manufacturing. Dubai’s industries are exploring increasingly intricate geometries, and high-detail engineering as a result of the growing demand for innovation and personalization. Because it can precisely execute even the most complex digital blueprints, beam laser cutting has opened up new design possibilities.

Complex CAD models can be seamlessly translated into reality thanks to this technology. Compromises can be avoided in the production of artistic buildings, precise electronic components, or creative architectural aspects. Reproducible fabrication of intricate geometric structures fosters innovation in real-world applications in addition to improving visual inventiveness. In this way, beam laser cutting has enabled industries in Dubai to overcome the design constraints imposed by traditional cutting methods.

Encouragement of Sustainability Objectives

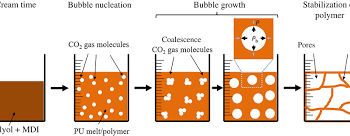

In recent years, Dubai’s manufacturing strategy has been impacted by its emphasis on sustainable development. By optimizing sheets or blocks and decreasing material waste through accurate cutting pathways, professional beam laser cutting helps to achieve this goal. By cutting as close to design patterns as feasible, laser-based systems optimize the use of raw material, in contrast to traditional instruments that leave a large amount of scrap behind.

Energy is also saved by requiring less secondary processing, and production waste is avoided by having fewer defective parts. Dubai places a high emphasis on environmentally friendly industrial processes; therefore, beam laser cutting is a great way to meet efficiency targets while also reducing expenses.

Combining Digital Manufacturing with Integration

Beam laser cutting perfectly fits in the processes of today because it can be used with digital design software, automation systems, and optimization systems that use AI. Digital input is used for design concepts, which are then processed by sophisticated software and applied to materials without the need for physical correction. Error rates are decreased, development cycles are shortened, and seamless alignment with automated manufacturing lines is guaranteed by this integration. Professional beam laser cutting has therefore emerged as a crucial component of Dubai’s transition to digitally driven production environments.

Dubai’s worldwide competitiveness

Using cutting-edge technologies like beam laser cutting helps Dubai become a more competitive and well-known manufacturing hub worldwide. These services make goods produced locally meet the requirements of quality in the world. Availability of high-tech processes, which provide the best quality in accuracy, design flexibility, and sustainability, is beneficial to both large and small manufacturing businesses.

Due to its competitiveness on the global level, Dubai can attract foreign investment and enhance the growth of domestic companies that are capable of meeting the challenging demands of the global markets. As a result, beam laser cutting has emerged as a force behind industrial development and a means of securing Dubai’s place on the global manufacturing map.

Prospects for Beam Laser Cutting in Dubai in the Future

As laser power, control systems, and system integration continue to increase, the potential of laser cutting in Dubai is expected to grow. The industry’s future is being shaped by the growing use of hybrid technologies, improved energy efficiency, and even 3D laser cutting. The necessity of smart electronics components, lightweight aircraft materials, and innovative design structures is expected to drive more integration of this technology.

Beam laser cutting will continue to be a significant component of defining the next phase of manufacturing perfection, and Dubai will strive to concentrate its investments and policies on the industries that are driven by innovation. It will continue transforming industries and production in the future because of its contribution to productivity, sustainability, and innovative design.

Conclusion

Beam laser cutting in Dubai has reshaped the manufacturing environment by combining accuracy, flexibility, and efficiency in a constant process. In addition to reducing waste and improving competitiveness, it helps industries to exceed boundaries. It is not merely a manufacturing tool, but professional beam laser cutting is a step forward in the Dubai ambition of production, innovation, and global industrial leadership.

The technology has made its mark as an engine of transformation in manufacturing by easily interconnecting with modern-day digital systems and operating across a wide spectrum of uses. Its ongoing existence is an indication of a larger narrative of development whereby Dubai positions itself as a technologically advanced and globally competitive industry role model.