Yoga leggings have become a core product in the activewear market, and meeting consumer demand requires efficient bulk production and well-organized supply chains. For brands, working with reliable yoga leggings manufacturers ensures timely delivery, consistent quality, and cost-effective production. Understanding how manufacturers manage large-scale production and supply chain operations helps brands make informed decisions and maintain a competitive edge in the market.

Bulk Production Capabilities

One of the primary aspects of working with yoga leggings manufacturers is their ability to handle bulk production. Bulk production involves creating large quantities of leggings while maintaining consistent quality across all units. Manufacturers achieve this by standardizing production processes, investing in advanced machinery, and implementing skilled labor practices.

A trusted Yoga Leggings Manufacturers can accommodate different order sizes, from small batch runs to high-volume production. They often use automated cutting machines, industrial sewing equipment, and quality inspection systems to ensure that every pair of leggings meets design and sizing specifications. Efficient bulk production allows brands to maintain inventory levels, meet seasonal demands, and reduce lead times.

Material Sourcing and Inventory Management

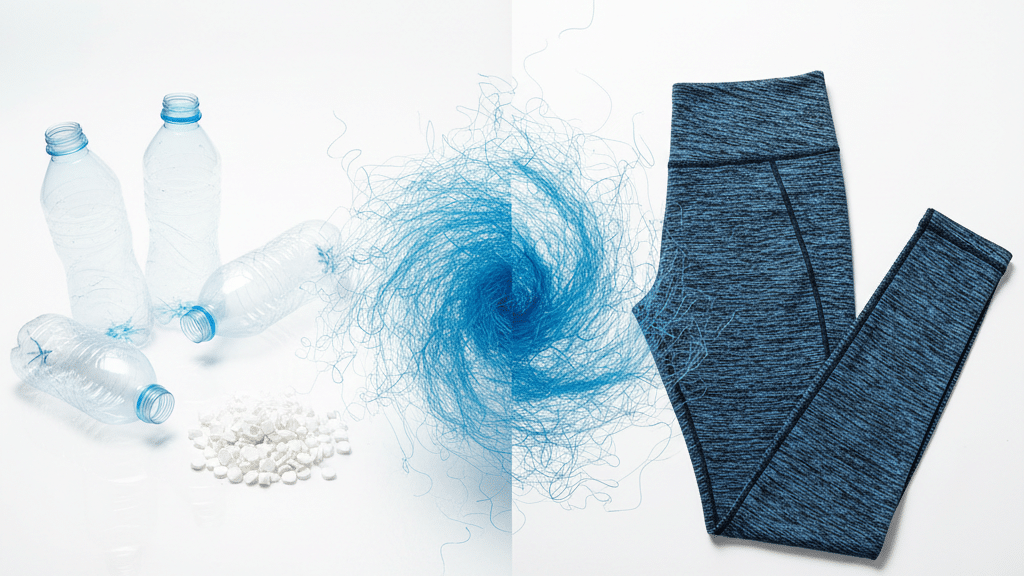

Bulk production relies heavily on reliable material sourcing and inventory management. Manufacturers typically maintain strong relationships with fabric suppliers to ensure a steady supply of high-quality materials such as spandex, polyester, nylon, and bamboo fibers. They also manage inventory levels to avoid production delays caused by shortages or overstocking.

Effective inventory management systems allow manufacturers to track fabric consumption, monitor stock levels, and reorder materials as needed. This ensures that bulk production runs smoothly and that brands receive consistent products on schedule. Sustainable sourcing practices, including the use of recycled and eco-friendly fabrics, are increasingly prioritized to meet environmental and consumer expectations.

Production Planning and Scheduling

Efficient production planning is essential for managing bulk orders. Yoga leggings manufacturers plan production schedules based on order volume, fabric availability, and shipping deadlines. This planning process ensures that resources are allocated effectively and that production timelines are met.

Manufacturers often divide production into stages, including cutting, stitching, quality inspection, and packaging. Each stage is carefully monitored to maintain consistent standards and prevent bottlenecks. Advanced software systems help track progress, optimize workflow, and coordinate with suppliers and logistics partners.

Quality Control and Consistency

Maintaining consistent quality in bulk production is a key focus for yoga leggings manufacturers. Quality control measures are implemented at multiple stages, from fabric inspection to final product checks. Manufacturers test garments for stretch, durability, colorfastness, and fit to ensure that every pair of leggings meets performance standards.

Random sampling, in-line inspections, and final audits help detect defects early, reducing the risk of faulty products reaching the market. Brands benefit from these stringent quality practices by receiving reliable products that uphold their reputation and meet consumer expectations.

Packaging and Labeling

Bulk production also requires careful attention to packaging and labeling. Manufacturers can provide customized packaging solutions, including branded tags, eco-friendly packaging materials, and bulk shipment options. Proper packaging protects the leggings during transit and ensures that they arrive in optimal condition.

Customized labeling, including size tags and brand logos, helps maintain brand identity and enhances customer experience. Efficient packaging practices also facilitate faster distribution and inventory management for brands.

Logistics and Supply Chain Coordination

A well-organized supply chain is critical for successful bulk production. Yoga leggings manufacturers coordinate logistics, including warehousing, shipping, and customs clearance, to ensure timely delivery of products. Many manufacturers offer international shipping solutions and work closely with logistics partners to optimize transportation routes and reduce lead times.

Supply chain transparency allows brands to track orders, anticipate delays, and respond to market demand effectively. By maintaining clear communication with suppliers and logistics providers, manufacturers minimize disruptions and ensure that bulk orders are fulfilled efficiently.

Continuous Improvement and Innovation

Leading yoga leggings manufacturers continually seek ways to improve their bulk production and supply chain practices. This includes adopting new technologies, optimizing production layouts, and exploring sustainable practices in material sourcing, energy usage, and waste management. Continuous improvement ensures that manufacturers can meet evolving market demands while maintaining quality and cost efficiency.

Conclusion

Bulk production and supply chain practices are fundamental to the success of yoga leggings brands. Manufacturers achieve efficient bulk production through standardized processes, skilled labor, reliable material sourcing, careful production planning, stringent quality control, and effective logistics management. Partnering with experienced Yoga Leggings Manufacturers ensures access to high-quality materials, consistent product output, and efficient supply chain solutions. By understanding and leveraging these practices, brands can deliver yoga leggings that meet consumer demand, maintain performance standards, and strengthen their market presence. Effective bulk production and supply chain management are essential for building a reliable and competitive brand in the activewear industry.